When grinding aluminum, choosing the right grinding wheel is critical to achieving the best results. Aluminum is a soft metal with unique properties that require specific abrasives to handle effectively. This article provides a comprehensive overview of the best grinding wheels for aluminum, including key features, recommended models, and comparisons.

Key Considerations for Roughing Aluminum

Aluminum presents several challenges during grinding due to its softness and tendency to clog abrasive materials. Therefore, it is essential to select the right type of grinding wheel to avoid problems such as overheating, clogging, and premature wear. Here are the main considerations:

- Abrasive Material: The choice of abrasive material is critical. Common abrasives include aluminum oxide, silicon carbide, and zirconium alumina. Each has its advantages and limitations depending on the application.

- Disc Type: Different types of grinding discs are suited for specific tasks, such as flap discs, resin bonded discs, and wire brushes. Understanding their functions helps you select the right one for your needs.

- Grit Size: The size of the abrasive grains affects the cutting efficiency of the disc and the quality of the finish. Finer grits are generally used for finishing, while coarser grits are better for fast material removal.

- Backing Material: The backing material of the disc can influence its durability and performance. It should be chosen based on the specific demands of the job.

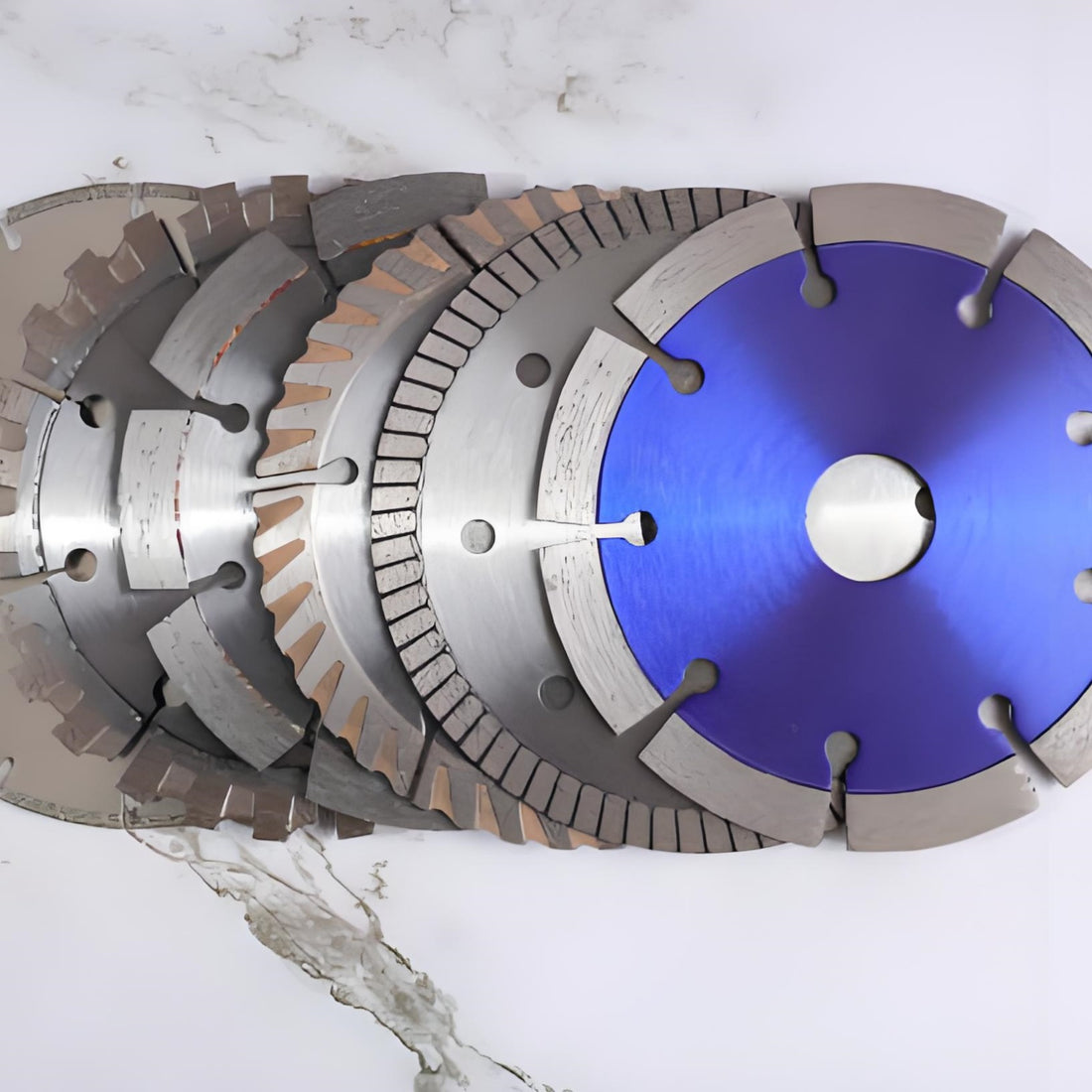

Types of Grinding Discs for Aluminum

1. Flap Discs

Flap discs are versatile and highly effective for grinding aluminum. They consist of overlapping abrasive flaps arranged around a central axis. Key benefits include:

- Cooling Effect : Flap discs have a built-in cooling effect due to the airflow created between the fins, which helps reduce heat build-up and prevent the aluminum from sticking to the disc.

- Flexibility : They conform well to different surfaces, making them ideal for both flat and contoured surfaces.

- Durability : High quality flap discs offer long-lasting performance and can handle a variety of aluminum alloys effectively.

Recommended Models :

- Weiler Abrasives ZIRCONIA FLAP DISC : Known for its durability and excellent performance on aluminum.

- 3M Cubitron II Flap Disc : Delivers superior cutting efficiency and a cooler grinding experience.

2. Resin Binder Discs

Resin bond discs are designed to handle high pressure applications and are suitable for grinding aluminum due to their ability to resist clogging. They are made by embedding abrasive grains in a resin matrix, providing a robust and reliable grinding surface.

- High Performance : These discs are effective for both rough grinding and finishing tasks.

- Clog Reduction : Resin binder helps keep the disc clean and functional for longer periods.

Recommended Models :

- Norton Quantum3 Resin-Bonded Disc : Delivers high performance and longevity.

- Walter Surface Technologies ZIP Discs : Provides excellent cut rate and clogging resistance.

3. Silicon Carbide Discs

Silicon carbide discs are specifically designed for grinding non-ferrous metals, including aluminum. Their sharp, hard abrasive grains are highly effective for removing material and achieving a smooth finish.

- Sharp Abrasive : Silicon carbide is known for its sharp cutting edges, making it ideal for soft metals.

- Finish Quality : Provides a smooth surface finish due to its fine abrasive particles.

Recommended Models :

- 3M Silicon Carbide Sanding Disc : Ideal for precision roughing and finishing of aluminum.

- Klingspor Silicon Carbide Disc : Known for its excellent cutting ability and surface finish.

4. Wire Brushes

Wire brushes, while not strictly grinding discs, are useful for cleaning and preparing aluminum surfaces. They help remove oxidation, scale, and debris before grinding or welding.

- Surface Preparation : Excellent for cleaning and deburring aluminum surfaces.

- Versatility : They can be used in combination with other roughing methods to obtain better results.

Recommended Models :

- Weiler Abrasives Wire Brush : Provides effective cleaning and surface preparation.

- Osborn Wire Brush : Known for its durability and performance in high demand applications.

Comparison of Grinding Discs for Aluminum

To help you choose the right disc, here is a comparison of the different types:

| Disk Type | Advantages | Disadvantages | Recommended Models |

| Flap Discs | Cooling effect, flexible, durable | May wear faster on rough surfaces | Weiler Abrasives ZIRCONIA, 3M Cubitron II |

| Resin Binder Discs | High performance, reduced clogging | It may be more expensive | Norton Quantum3, Walter ZIP Discs |

| Silicon Carbide Discs | Sharp abrasive, smooth finish | Not ideal for heavy stock removal | 3M Silicon Carbide, Klingspor |

| Wire Brushes | Effective, versatile cleaning | It is not a grinding disc | Weiler Abrasives, Osborn |

Tips for Effective Aluminum Grinding

- Use the Proper Speed : Make sure to use the grinding wheel at the recommended speed to avoid overheating and damage.

- Maintain Disk Health : Check and replace disks regularly to ensure efficient performance.

- Use Proper Techniques : Use constant pressure and avoid excessive force to extend disc life and achieve best results.

Conclusion

Selecting the right grinding wheel for aluminum involves understanding the specific requirements of your task and the characteristics of the different types of wheels. Flap wheels, resin bond wheels, silicon carbide wheels, and wire brushes all offer unique benefits and applications. By considering the factors described and choosing the appropriate wheel for your needs, you can achieve efficient, high-quality results on aluminum grinding tasks.

I hope the above information is useful to you. If you want to know more details about cutting discs, go to https://flamingoherramientas.com/ to obtain it.