1. Basic composition of the discs

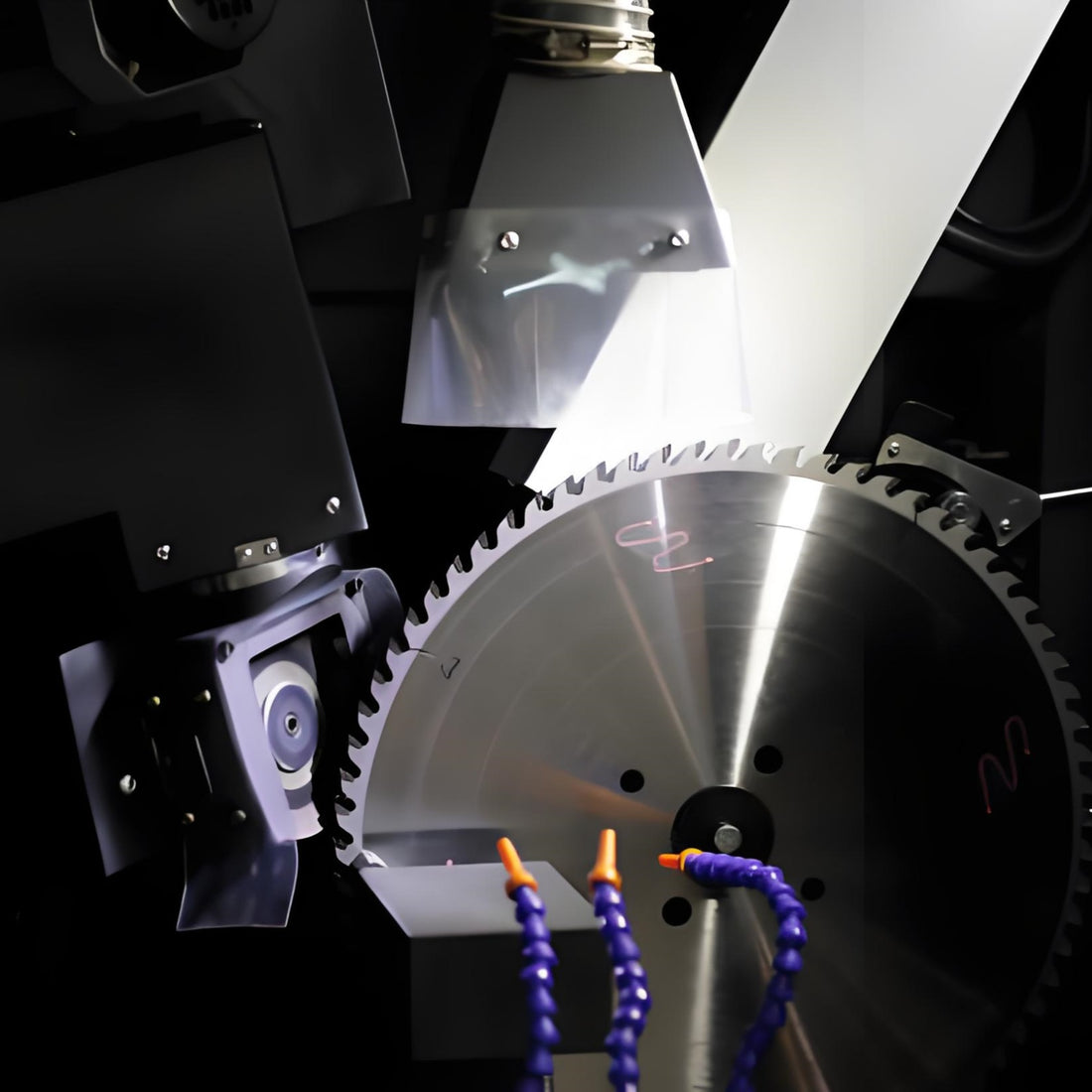

Generally, diamond blades consist of two main parts: the steel core and the cutting teeth. The steel core provides structural support to the blade, while the cutting teeth are the part that comes into direct contact with the work material. Depending on the use and the manufacturing process, the materials of the cutting teeth can vary, with one of the most common being diamond.2. Diamonds on the cutting teeth

Diamond cutting teeth are not made directly from solid diamonds as is often thought. In fact, diamonds are most commonly used in the form of powder or small granules. These diamond granules are fixed in the matrix of the cutting teeth, typically through metal or alloys.

3. Manufacturing process and technology

The manufacturing of diamond blades involves advanced processes and technologies. Manufacturers carefully select manufacturing techniques that ensure uniform distribution of diamond grits on the cutting surface and guarantee stability and durability during use. This process not only requires high-precision equipment, but also strict quality control and testing.4. Functions and advantages of diamonds

Even though the number of diamonds in a blade may be relatively small, their function is crucial. Diamonds are extremely hard and wear-resistant, allowing diamond blades to effectively handle a wide range of materials and hardnesses. This advantage makes diamond blades ideal for applications in construction, stone processing, and other fields.5. Industry acceptance and standards

The use of diamond blades is subject to strict industry standards and certifications. Manufacturers typically adhere to internationally recognized quality standards to ensure their products meet safety and performance requirements. These standards range from the selection of raw materials to the quality testing of finished products, providing a reliable guarantee for users.6. Market selection and recommendations

When choosing diamond blades, it is advisable for consumers to consider the brand, manufacturer reputation, and product certifications. High-quality diamond blades not only improve cutting efficiency and durability, but also reduce safety risks and operating costs. Therefore, it is recommended to choose certified brands and suppliers to ensure the best user experience and long-term return on investment.Conclusion

In short, diamond blades do indeed contain diamonds, though not in the form commonly imagined. Diamonds, with their superior physical characteristics, play a crucial role in blade manufacturing, improving the efficiency and durability of tools. Understanding the composition and advantages of diamond blades can help you make informed decisions that meet the needs of different projects and applications.I hope this article provides you with clear answers and valuable reference information. If you have any further questions or need additional help, please feel free to contact me https://flamingoherramentas.com/ !